BRSO 750

FAQ – BRSO 750

BRSO 750 is a blown oil – a vegetable oil with increased viscosity obtained through controlled polymerization. It retains its natural lubricating properties while providing higher viscosity and improved stability.

It is used as a natural viscosity modifier and raw material for cutting oils, emulsions, greases, paints, varnishes, detergents, soaps, linseed oils, and other industrial products.

Yes, BRSO 750 mixes very well with other types of oils and is often used to increase viscosity and improve lubricity in oil blends.

- Excellent lubricating properties

- Rapid biodegradability (> 60% / 28 days according to OECD 301D)

- Good thermo-oxidative stability

- High viscosity suitable for special applications

- Good low-temperature performance

Kinematic viscosity at 40 °C ranges from 675–825 mm²/s, classifying it as a high-viscosity oil.

Pour point is below −15 °C, ensuring good handling and processability even at low temperatures.

Yes, the oil is rapidly biodegradable and suitable for applications where environmental impact is a priority.

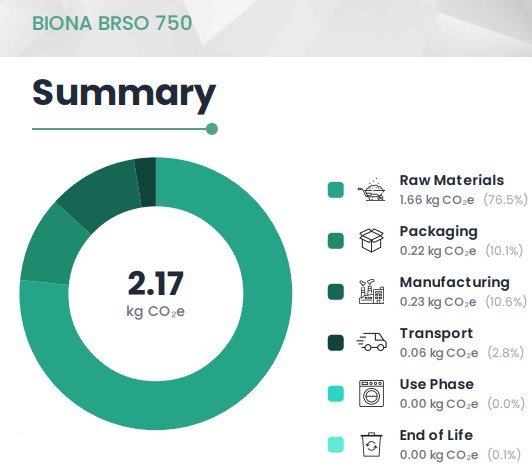

Product Carbon Footprint

2.17 kg CO₂e / 1 L

Overview of Product Carbon Footprint (PCF) results

Documents

- Technical Data Sheet (TDS) – (download)

- Safety Data Sheet (MSDS) – available on request

Parameters

| Density at 20 °C | 945 – 995 kg/m3 |

|---|---|

| Kin. viscosity at 40 °C | The viscosity of a fluid is a measure of its resistance to gradual deformation by shear stress or tensile stress. 675-825 cSt |

| Pour Point | The pour point of a liquid is the temperature below which the liquid loses its flow characteristics. -15 °C |

| Flash Point | The lowest temperature at which enough vapor escapes from a heated sample above its surface into the air that the resulting mixture of vapor and air ignites when an auxiliary flame is brought close to it and then extinguishes again. > 220 °C |

| Biodegradability in 28 days | Biologically sufficiently rapid decomposition of oil without effect on fauna and flora. Biological decomposition monitored by dissolved oxygen analysis over 28 days. >60 % |

| ISO-VG viscosity classification | ISO VG 750 |

Producer of bio-oils and plastic lubricants

Producer of bio-oils and plastic lubricants 1 l

1 l 5 l

5 l 10 l

10 l 20 l

20 l 60 l

60 l 200 l

200 l 1000 l

1000 l